#Structural Adhesive

Explore tagged Tumblr posts

Text

Structural Adhesives: A Perfect Guide To Learn About Them

If you have been searching for a structural adhesive, you may feel confused about your choices since there are so many options available in the market. It helps join different types of surfaces. Navigating through different industrial adhesive options can be complicated for anyone. But with the help of correct information, you can make an efficient choice. Let’s discuss more about it. Using structural adhesive Structural adhesive can be perfect for applications where you require some stiffness or strength. If you do not have time to prepare the surface, it can be a versatile choice. Even when the bond lines have gaps, it will be a great option. If you want to fill for sealing and protecting, you can rely on structural adhesives. If you choose epoxy adhesives, they will have exceptional strength. Moreover, they will also have environmentally resistant properties. Things to consider when shopping for structural adhesives Flexibility: Several people think that flexibility is one of the most essential requirements. It is a crucial deciding factor that you may consider when looking for structural adhesives. These adhesives should be suitable even when there are movements. Cure time Adhesives are used in different types of businesses and industries. Therefore, the cure time is an essential factor to consider. In several situations, you may not have a lot of time to spend. So, you must choose adhesives that can cure quickly. It will help you save time. It will also be beneficial for you when you have a large area to take care of. Making the most informed decision Your search for the best methacrylate adhesive may not be as easy as it seems. You should ideally look for the one that offers great strength and flexibility. Moreover, the option should also offer a short cure time. If it can provide you with durable results, it will be even better in the long term. Hence, you can work with trusted companies that offer various options and can easily decide on the most suitable adhesive that matches the application. About ITW Performance Polymers: ITW Performance Polymers is one of the most renowned companies that can help you when you require metal to metal adhesive. On its website, you can find various adhesive options. It focuses on providing complete satisfaction to clients. So, it will be your one-stop destination for all adhesive needs. To get more details, visit https://itwperformancepolymers.com/

Original source: https://bit.ly/4cnuBBy

0 notes

Text

What is Structural Epoxy Used For?

Structural epoxy is a powerful adhesive designed for demanding applications, providing exceptional strength and durability. Known for its high-performance properties, structural epoxy is widely used in various industries to bond and reinforce materials, ensuring long-lasting and reliable connections.

Key Applications of Structural Epoxy

Aerospace Industry: One of the primary users of structural epoxy is the aerospace industry. Aerospace structural adhesive, such as those provided by Kohesi Bond, is crucial for bonding aircraft components. These adhesives offer superior strength and resistance to extreme conditions, making them ideal for critical aerospace applications.

Automotive Sector: Structural bonding adhesives are extensively used in the automotive industry for assembling car parts. From bonding body panels to reinforcing chassis components, structural epoxy ensures that vehicles are both lightweight and strong, improving fuel efficiency and safety.

Construction and Infrastructure: In construction, structural epoxy is used for repairing and reinforcing concrete structures. It provides robust adhesion to steel and other building materials, making it a go-to solution for structural bonding in bridges, buildings, and other infrastructure projects.

Marine Applications: Structural epoxy is also employed in the marine industry for bonding and sealing components exposed to harsh aquatic environments. Its waterproof properties and resistance to saltwater make it an excellent choice for boat construction and repair.

Electronics: In electronics, structural adhesives are used to secure components and protect them from environmental factors. The strongest structural adhesive ensures that electronic devices remain functional under varying conditions.

Why Choose Structural Epoxy?

Structural epoxy is preferred for its versatility and reliability. It offers excellent mechanical properties, including high tensile and shear strength, making it the strongest structural adhesive available. Adhesive manufacturers in India, such as Kohesi Bond, produce high-quality epoxy adhesives that cater to diverse industrial needs.

For industries looking for robust solutions, structural epoxy provides unmatched performance, ensuring durable and resilient bonds across various applications.

Choose Kohesi Bond for your structural epoxy needs and experience the pinnacle of adhesive technology in India.

#Structural Epoxy#Structural Adhesive#Aerospace Structural Adhesive#Aircraft Adhesive Bonding#Structural Bonding#Epoxy Structural Adhesive#Structural Glue#Types of Structural Adhesives#Strongest Structural Adhesive#Adhesive Manufacturer in India#Epoxy Adhesive India#Kohesi Bond#Automotive Structural Adhesive#Industrial Adhesives#High-Performance Adhesives#Structural Bonding Adhesive#Structural Epoxy Applications

1 note

·

View note

Text

One-step synthesis of Janus hydrogel

Janus adhesive hydrogels hold promising applications across health care fields. Nevertheless, a simple method to synthesize the material had yet to be bioengineered in the lab. In a new study now published in Science Advances, Huowen Chen and a research team in China devised a simple method to prepare Janus hydrogels based on fundamental phenomena including the self-aggregation of surfactants at high concentrations at the air/water interface. The team combined a small amount of sodium-alpha-linoleate with acrylamide through free radical polymerization and synthesized the Janus adhesive hydrogels. These constructs showed remarkable adhesive strength, chemical properties, and surface morphology, which the team investigated using molecular dynamics simulations to understand the mechanisms of the biomaterial's properties.

Read more.

7 notes

·

View notes

Text

having to make a spreadsheet just to keep track of all my starfield outposts

#all i wanted was some fucking adhesive#i need to create an outpost JUST for a place for all this shit to be delivered to#make an outpost on gagarin for the adhesive then on another planet for the fluorine needed for it#then another for the nickel copper and tungsten i need for components#and another for structural material and sealant#it never eends#kinda wish fallout 4 settlements did something like this tbh#without mods

1 note

·

View note

Text

Structural Adhesive for New Energy Vehicles Market, Global Outlook and Forecast 2025-2032

Structural adhesive for new energy vehicles is a high-performance adhesive specifically developed for bonding and fixing vehicle structural components in the manufacturing process. Unlike traditional mechanical fastening methods, structural adhesives enhance the overall integrity of the vehicle. They improve the structural strength, reduce weight, minimize vibrations and noise, and bolster corrosion resistance, making them an essential component in the production of modern new energy vehicles.

Market Size

Download FREE Sample of this Report @ https://www.statsmarketresearch.com/download-free-sample/8027813/global-structural-adhesive-for-new-energy-vehicles-forecast-2025-2032-477

The global structural adhesive market for new energy vehicles was valued at approximately USD 1,098 million in 2024. The market is projected to grow significantly, reaching an estimated USD 5,097.59 million by 2032, with a robust compound annual growth rate (CAGR) of 18.60% during the forecast period.

Regional Highlights:

North America: The structural adhesive market in North America was estimated at USD 384.61 million in 2024, with a projected CAGR of 15.94% from 2025 to 2032.

Asia-Pacific: This region is anticipated to lead in market growth, driven by a surge in electric vehicle production and demand in countries like China and Japan.

Europe: Europe’s market is expected to benefit from stringent environmental regulations and a focus on reducing vehicle emissions.

North America: The structural adhesive market in North America was estimated at USD 384.61 million in 2024, with a projected CAGR of 15.94% from 2025 to 2032.

Asia-Pacific: This region is anticipated to lead in market growth, driven by a surge in electric vehicle production and demand in countries like China and Japan.

Europe: Europe’s market is expected to benefit from stringent environmental regulations and a focus on reducing vehicle emissions.

Market Dynamics (Drivers, Restraints, Opportunities, and Challenges)

Drivers

Increased Adoption of Electric Vehicles: As governments worldwide promote electric vehicle adoption, the demand for lightweight, durable, and efficient components like structural adhesives has surged.

Regulatory Push for Emission Reduction: Stringent environmental regulations are driving automakers to replace traditional fasteners with adhesives to reduce vehicle weight and improve fuel efficiency.

Technological Advancements: Continuous innovations in adhesive formulations, such as enhanced bonding strength and thermal resistance, are expanding their applications.

Increased Adoption of Electric Vehicles: As governments worldwide promote electric vehicle adoption, the demand for lightweight, durable, and efficient components like structural adhesives has surged.

Regulatory Push for Emission Reduction: Stringent environmental regulations are driving automakers to replace traditional fasteners with adhesives to reduce vehicle weight and improve fuel efficiency.

Technological Advancements: Continuous innovations in adhesive formulations, such as enhanced bonding strength and thermal resistance, are expanding their applications.

Restraints

High Initial Costs: The cost of high-performance adhesives can be prohibitive, especially for small-scale manufacturers.

Limited Awareness: Some manufacturers remain unaware of the benefits and potential applications of structural adhesives, hindering broader market penetration.

High Initial Costs: The cost of high-performance adhesives can be prohibitive, especially for small-scale manufacturers.

Limited Awareness: Some manufacturers remain unaware of the benefits and potential applications of structural adhesives, hindering broader market penetration.

Opportunities

Emerging Markets: Rapid industrialization and growing demand for new energy vehicles in emerging economies present untapped potential.

Sustainability Trends: The shift towards eco-friendly and sustainable manufacturing processes opens opportunities for the development of bio-based adhesives.

Emerging Markets: Rapid industrialization and growing demand for new energy vehicles in emerging economies present untapped potential.

Sustainability Trends: The shift towards eco-friendly and sustainable manufacturing processes opens opportunities for the development of bio-based adhesives.

Challenges

Application Complexity: Proper application of structural adhesives requires specialized training and equipment, which can pose challenges for manufacturers.

Raw Material Availability: Fluctuations in the availability and cost of raw materials used in adhesive production can impact market stability.

Application Complexity: Proper application of structural adhesives requires specialized training and equipment, which can pose challenges for manufacturers.

Raw Material Availability: Fluctuations in the availability and cost of raw materials used in adhesive production can impact market stability.

Regional Analysis

North America

The North American market benefits from a robust automotive industry and supportive government policies encouraging electric vehicle adoption. Major players in the region focus on research and development to enhance adhesive performance and meet evolving industry demands.

Europe

Europe’s focus on sustainability and stringent emission regulations has accelerated the adoption of structural adhesives. Countries like Germany and France lead in innovation and production of new energy vehicles, further driving market growth.

Asia-Pacific

Asia-Pacific dominates the global market, with China emerging as a key player due to its massive production and consumption of electric vehicles. Government incentives and growing awareness about eco-friendly vehicles contribute to the region’s market expansion.

Rest of the World

South America, the Middle East, and Africa are gradually catching up, with increased investments in electric vehicle infrastructure and manufacturing capabilities.

Competitor Analysis

The structural adhesive market for new energy vehicles is highly competitive, with key players focusing on innovation, strategic partnerships, and geographical expansion. Major companies include:

Henkel: Renowned for its advanced adhesive solutions tailored for the automotive industry.

Sika: Offers a wide range of high-performance adhesives for various applications.

Arkema Group: Specializes in innovative adhesive technologies to meet the evolving needs of the automotive sector.

3M: A global leader in adhesives, providing cutting-edge solutions for structural bonding.

Illinois Tool Works: Known for its comprehensive range of adhesive products.

Henkel: Renowned for its advanced adhesive solutions tailored for the automotive industry.

Sika: Offers a wide range of high-performance adhesives for various applications.

Arkema Group: Specializes in innovative adhesive technologies to meet the evolving needs of the automotive sector.

3M: A global leader in adhesives, providing cutting-edge solutions for structural bonding.

Illinois Tool Works: Known for its comprehensive range of adhesive products.

Market Segmentation (by Application)

Body-in-White (BIW)

Structural adhesives are extensively used in BIW to enhance rigidity, reduce weight, and improve crash resistance.

Automotive Electronics

Adhesives play a crucial role in securing and protecting sensitive electronic components in new energy vehicles.

Other Applications

Other applications include bonding interior components, sealing joints, and providing thermal insulation.

Market Segmentation (by Type)

Urethane

Urethane adhesives are known for their flexibility and impact resistance, making them suitable for dynamic applications.

Epoxy

Epoxy adhesives offer excellent structural strength and durability, widely used in critical load-bearing applications.

Acrylic

Acrylic adhesives provide rapid bonding and are often used for lightweight materials.

Other Types

This includes silicone and hybrid adhesives designed for specialized applications.

Key Company

Henkel

Sika

Arkema Group

3M

Illinois Tool Works

Huitian Adhesive

ThreeBond

Uniseal

Sunstar

H.B. Fuller

PPG

Parker Hannifin

Unitech

Jowat

DuPont

Darbond

Henkel

Sika

Arkema Group

3M

Illinois Tool Works

Huitian Adhesive

ThreeBond

Uniseal

Sunstar

H.B. Fuller

PPG

Parker Hannifin

Unitech

Jowat

DuPont

Darbond

Geographic Segmentation

North America: USA, Canada, Mexico

Europe: Germany, UK, France, Russia, Italy, Rest of Europe

Asia-Pacific: China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific

South America: Brazil, Argentina, Columbia, Rest of South America

The Middle East and Africa: Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA

North America: USA, Canada, Mexico

Europe: Germany, UK, France, Russia, Italy, Rest of Europe

Asia-Pacific: China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific

South America: Brazil, Argentina, Columbia, Rest of South America

The Middle East and Africa: Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA

FAQ Section

What is the current market size of structural adhesives for new energy vehicles?

The global market size was estimated at USD 1,098 million in 2024.

Which are the key companies operating in this market?

Major players include Henkel, Sika, Arkema Group, 3M, and Illinois Tool Works.

What are the key growth drivers in this market?

Key drivers include increased electric vehicle adoption, regulatory push for emission reduction, and technological advancements in adhesive formulations.

Which regions dominate this market?

Asia-Pacific dominates the market, with North America and Europe also showing significant growth.

What are the emerging trends in this market?

Emerging trends include the development of bio-based adhesives, increased focus on lightweight materials, and growing investments in electric vehicle infrastructure.

Key Benefits of This Market Research:

Industry drivers, restraints, and opportunities covered in the study

Neutral perspective on the market performance

Recent industry trends and developments

Competitive landscape & strategies of key players

Potential & niche segments and regions exhibiting promising growth covered

Historical, current, and projected market size, in terms of value

In-depth analysis of the Structural Adhesive for New Energy Vehicles Market

Overview of the regional outlook of the Structural Adhesive for New Energy Vehicles Market:

Key Reasons to Buy this Report:

Access to date statistics compiled by our researchers. These provide you with historical and forecast data, which is analyzed to tell you why your market is set to change

This enables you to anticipate market changes to remain ahead of your competitors

You will be able to copy data from the Excel spreadsheet straight into your marketing plans, business presentations, or other strategic documents

The concise analysis, clear graph, and table format will enable you to pinpoint the information you require quickly

Provision of market value data for each segment and sub-segment

Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market

Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region

Competitive landscape which incorporates the market ranking of the major players, along with new service/product launches, partnerships, business expansions, and acquisitions in the past five years of companies profiled

Extensive company profiles comprising of company overview, company insights, product benchmarking, and SWOT analysis for the major market players

The current as well as the future market outlook of the industry concerning recent developments which involve growth opportunities and drivers as well as challenges and restraints of both emerging as well as developed regions

Includes in-depth analysis of the market from various perspectives through Porter

Get the Complete Report & TOC @ https://www.statsmarketresearch.com/global-structural-adhesive-for-new-energy-vehicles-forecast-2025-2032-477-8027813

Table of content

Table of Contents 1 Research Methodology and Statistical Scope 1.1 Market Definition and Statistical Scope of Structural Adhesive for New Energy Vehicles 1.2 Key Market Segments 1.2.1 Structural Adhesive for New Energy Vehicles Segment by Type 1.2.2 Structural Adhesive for New Energy Vehicles Segment by Application 1.3 Methodology & Sources of Information 1.3.1 Research Methodology 1.3.2 Research Process 1.3.3 Market Breakdown and Data Triangulation 1.3.4 Base Year 1.3.5 Report Assumptions & Caveats 2 Structural Adhesive for New Energy Vehicles Market Overview 2.1 Global Market Overview 2.1.1 Global Structural Adhesive for New Energy Vehicles Market Size (M USD) Estimates and Forecasts (2019-2032) 2.1.2 Global Structural Adhesive for New Energy Vehicles Sales Estimates and Forecasts (2019-2032) 2.2 Market Segment Executive Summary 2.3 Global Market Size by Region 3 Structural Adhesive for New Energy Vehicles Market Competitive Landscape 3.1 Global Structural Adhesive for New Energy Vehicles Sales by Manufacturers (2019-2025) 3.2 Global Structural Adhesive for New Energy Vehicles Revenue Market Share by Manufacturers (2019-2025) 3.3 Structural Adhesive for New Energy Vehicles Market Share by Company Type (Tier 1, Tier 2, and Tier 3) 3.4 Global Structural Adhesive for New Energy Vehicles Average Price by Manufacturers (2019-2025) 3.5 Manufacturers Structural Adhesive for New Energy Vehicles Sales Sites, Area Served, Product Type 3.6 Structural Adhesive for New Energy Vehicles M

Customize/Section/Part Purchase @ https://www.statsmarketresearch.com/chapters-purchase/8027813/global-structural-adhesive-for-new-energy-vehicles-forecast-2025-2032-477

CONTACT US: 276 5th Avenue, New York, NY 10001, United States International: +1(646)-781-7170 / +91 8087042414

Check other links >>> https://www.linkedin.com/feed/update/urn:li:activity:7287737781894737923 https://www.linkedin.com/feed/update/urn:li:activity:7287748171135356929 https://www.linkedin.com/feed/update/urn:li:activity:7287759356140384256 https://www.linkedin.com/feed/update/urn:li:activity:7287769156207153153 https://www.linkedin.com/feed/update/urn:li:activity:7287779954430255105

0 notes

Text

https://www.intellectualmarketinsights.com/report/structural-adhesives-market-growth-and-trends/imi-003143

0 notes

Text

The Growing Structural Adhesives Market: Key Trends and Future Outlook

Structural adhesives have become a pivotal solution in various industries, offering robust bonding for a wide range of applications. Whether in aerospace, automotive, construction, or electronics, the market for these high-performance adhesives is expanding rapidly due to their capacity to replace traditional fastening methods such as welding or riveting.

Market Overview

The structural adhesives market is projected to grow at a compound annual growth rate (CAGR) of 5.5% from 2024 to 2029, driven by several factors, including the rising demand for lightweight materials and innovations in adhesive technologies. By 2029, the market is expected to be worth USD 17.7 billion, highlighting the increasing reliance on advanced bonding solutions across industries. Notably, the automotive sector is a leading contributor to this growth due to the demand for adhesives that enable lighter and more fuel-efficient vehicles.

Key Growth Drivers

Demand for Lightweight Materials: One of the primary drivers fueling the rise of structural adhesives is the growing use of lightweight materials, particularly in industries such as automotive and aerospace. Adhesives offer a unique advantage over traditional mechanical fasteners, as they not only provide excellent bonding strength but also help reduce the weight of components. In the automotive industry, for instance, structural adhesives are widely used to bond dissimilar materials, such as metals and composites, which results in lighter vehicles and improved fuel economy.

Sustainability and Environmental Concerns: Sustainability has become a major concern for manufacturers globally. Adhesives contribute to more environmentally friendly production processes by reducing the need for energy-intensive techniques like welding. They also help decrease material waste during production. As industries look to lower their carbon footprint, the use of adhesives is becoming increasingly aligned with sustainability goals.

Technological Advancements: The continuous innovation in adhesive technologies is pushing the market forward. Modern structural adhesives are designed to perform in extreme conditions, offering high resistance to temperature variations, corrosion, and fatigue. Recent developments have introduced hybrid adhesives, which combine the properties of epoxy, acrylic, and polyurethane adhesives, offering superior performance across various applications. This innovation is crucial for industries like electronics, where precision and reliability are paramount.

Construction Sector Growth: In the construction industry, adhesives are being used more extensively, particularly for bonding glass and metal in modern architectural designs. Structural adhesives provide an aesthetic advantage by creating seamless joints, while also ensuring the structural integrity of the bonded components. Additionally, as the demand for eco-friendly building materials rises, adhesives that contribute to green building initiatives are gaining more prominence in the market.

Key Industry Applications

Automotive Industry: The automotive sector is a major consumer of structural adhesives, particularly as the shift towards electric vehicles (EVs) accelerates. Adhesives help reduce the overall weight of EVs, improving battery efficiency and range. Additionally, adhesives improve crash performance and load distribution, contributing to enhanced vehicle safety.

Aerospace Sector: Structural adhesives are playing an increasingly important role in aerospace, where weight reduction and fuel efficiency are top priorities. These adhesives are used extensively to bond composite materials, which are lighter than metals but just as strong, making them ideal for modern aircraft design.

Electronics Industry: In the electronics industry, structural adhesives are critical for bonding delicate components in smartphones, computers, and other devices. These adhesives provide the necessary durability while allowing for miniaturization, which is a key trend in consumer electronics.

Construction Sector: The construction industry is experiencing a surge in the use of adhesives for bonding materials such as glass and metal in both residential and commercial projects. With the growing emphasis on green building practices, adhesives that reduce the environmental impact of construction processes are gaining traction. Additionally, adhesives enable more innovative designs, providing architects with greater flexibility in creating aesthetically pleasing structures.

Regional Market Insights

Globally, the structural adhesives market is thriving, with North America and Europe leading the charge. In North America, the automotive and aerospace industries are major consumers, while in Europe, stringent environmental regulations are driving the adoption of more sustainable adhesive solutions. The Asia-Pacific region is expected to experience the highest growth rate, fueled by rapid industrialization, infrastructure development, and the increasing production of electric vehicles in countries like China, Japan, and India.

Future Outlook

The future of the structural adhesives market looks promising as industries continue to prioritize lightweight, durable, and sustainable bonding solutions. With ongoing advancements in adhesive technologies and the rising demand for eco-friendly materials, structural adhesives are set to play an increasingly significant role across various sectors. From automotive to construction, the ability of adhesives to enhance performance while reducing environmental impact makes them an essential component in modern manufacturing.

To know more Download PDF Brochure :

The structural adhesives market is on a robust growth path, supported by technological innovations and the shift towards more sustainable industrial practices. As industries across the globe continue to evolve, the demand for high-performance adhesives that meet the complex requirements of modern manufacturing is expected to grow, cementing their importance in the future of several key industries.

#Tags:#Structural Adhesives Market#Adhesive Technology Trends#Lightweight Materials#Industrial Adhesives#Automotive Adhesives#Aerospace Adhesives

0 notes

Text

Structural Adhesive Market: Trends, Growth, and Future Outlook

The structural adhesive market has been experiencing significant growth in recent years, driven by increasing demand across various industries including automotive, aerospace, construction, and electronics. Structural adhesives are essential for creating strong, durable bonds between different materials, offering numerous advantages such as enhanced performance, reduced weight, and improved aesthetics. This article provides a comprehensive overview of the structural adhesive market, exploring key trends, growth factors, and future prospects.

Market Overview

Structural adhesives are high-performance bonding agents used to join load-bearing structures. These adhesives are designed to provide long-lasting bonds and withstand various environmental conditions such as temperature fluctuations, moisture, and chemical exposure. Common types of structural adhesives include epoxy, polyurethane, acrylic, and cyanoacrylate, each offering unique properties tailored to specific applications.

Key Trends Driving Market Growth

1. Rising Demand in Automotive Industry: The automotive sector is one of the largest consumers of structural adhesives. The shift towards lightweight materials to improve fuel efficiency and reduce emissions has led to increased use of adhesives for bonding different substrates such as metals, plastics, and composites. Structural adhesives are crucial in manufacturing processes, contributing to vehicle safety, durability, and performance.

2. Advancements in Aerospace Applications: The aerospace industry requires adhesives that can withstand extreme conditions while ensuring the integrity of critical components. Structural adhesives are extensively used in aircraft manufacturing for bonding metals and composites, enhancing structural strength and reducing weight. Innovations in adhesive formulations have led to improved performance, making them indispensable in modern aerospace engineering.

3. Growing Construction Activities: The construction sector is witnessing a surge in the adoption of structural adhesives for various applications, including bonding concrete, metals, and insulation materials. These adhesives offer superior bonding strength and durability, making them ideal for demanding construction projects. The trend towards sustainable construction practices further boosts the demand for eco-friendly adhesive solutions.

4. Electronics and Consumer Goods: Structural adhesives play a vital role in the electronics industry, where they are used to assemble components and protect delicate circuits from environmental factors. The miniaturization of electronic devices and the increasing complexity of assemblies drive the need for high-performance adhesives that provide reliable bonds and thermal management.

For a comprehensive analysis of the market drivers:- https://univdatos.com/report/structural-adhesive-market/

Market Dynamics

Drivers

- Technological Advancements: Ongoing research and development activities have led to the introduction of advanced adhesive formulations with enhanced properties such as faster curing times, higher bond strength, and improved resistance to environmental factors. These innovations drive market growth by meeting the evolving needs of various industries.

- Environmental Regulations: Stringent regulations aimed at reducing volatile organic compounds (VOCs) and promoting sustainable practices have led to the development of eco-friendly adhesives. Manufacturers are focusing on producing low-VOC and solvent-free adhesives, aligning with global environmental standards and catering to environmentally conscious consumers.

- Increasing Infrastructure Development: Rapid urbanization and infrastructure development, especially in emerging economies, create a significant demand for structural adhesives. The need for efficient bonding solutions in construction projects, including bridges, tunnels, and high-rise buildings, fuels market expansion.

Challenges

- High Cost of Advanced Adhesives: While advanced structural adhesives offer superior performance, their high cost can be a barrier to widespread adoption, particularly in price-sensitive markets. Balancing cost and performance remains a challenge for manufacturers.

- Technical Limitations: Despite advancements, certain technical limitations such as limited heat resistance and difficulties in bonding specific substrates can hinder market growth. Continuous research and development efforts are essential to address these challenges and expand the application range of structural adhesives.

For a sample report, visit:- https://univdatos.com/get-a-free-sample-form-php/?product_id=31065

Future Outlook

The structural adhesive market is poised for robust growth in the coming years, driven by technological advancements, increasing industrial applications, and the push for sustainable solutions. The development of new adhesive formulations with improved properties and the expansion of applications in emerging sectors such as renewable energy and medical devices present significant opportunities for market players.

In conclusion, the structural adhesive market is evolving rapidly, with increasing demand across various industries due to their ability to provide strong, durable bonds and enhance overall performance. Continued innovation and a focus on sustainability will be key to unlocking new growth avenues and maintaining the upward trajectory of the market.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

#Structural Adhesive Market#Structural Adhesive Market Growth#Structural Adhesive Market Share#Structural Adhesive Market Forecast

0 notes

Text

Reasons to Trust Products from ITW Performance Polymers

Designing and constructing structures is easy. However, everything gets difficult when one starts using them. The resultant wear and tear often become a problem. These issues can be addressed with the help of the best repair and maintenance techniques. The strongest epoxy for metal, concrete, rubber, etc., helps restore the durability, longevity, and performance of these structures easily.

ITW Performance Polymers is one of those online stores that deliver all the necessary chemical compounds for industrial and commercial purposes. The available adhesives, epoxies, and other repair compounds at this store are worth checking out. Here's why you need to visit the store.

Solution for All:

Different types of materials are used for industrial operations, manufacturing processes, and so on. For instance, concrete is preferred for constructing industrial premises. Metal structures are used to construct machinery, equipment, tools, etc.

These materials need maintenance and repair regularly. However, you can not use the same type of epoxies and adhesives for different surfaces. ITW Performance Polymers makes sure to give you what you need. You can find epoxies, adhesives, and other compounds for metals, concrete, rubbers, and several other surfaces. So, make sure to check it out now.

Modern Products for You:

Repair and maintenance used to be a complex task. The need for better solutions seemed higher due to this. Industries needed compounds that worked fast and helped them restore their operations as soon as possible.

ITW Performance Polymers is an excellent store with products like methacrylate adhesive, structural adhesive, and more. These products made everything easier than before. For instance, one can easily apply these solutions. Moreover, the downtime didn't seem like a problem anymore. Therefore, it is better for industries to check out the best products at this online store.

Top Brands Under One Roof:

Different brands excel in formulating and manufacturing different types of compounds for the repair and maintenance of metal, rubber, and concrete structures. However, industries need all these adhesives and epoxies to continue better working all the time. For instance, the best structural adhesive helps maintain the metal and concrete structures in the industries.

ITW Performance Polymers is one of the best online stores that bring every quality manufacturer under one roof. You can find brands like Devcon, Plexus, Epocast, Insulcast, etc., at this store.

Find out more at https://itwperformancepolymers.com/

Original Source: https://bit.ly/3WwHnWP

0 notes

Text

A Deep Dive into Structural Adhesives

At Kohesi Bond, we understand the critical role strong, reliable bonds play in various industries. But when it comes to applications demanding exceptional strength and durability, structural adhesives take center stage.

What are Structural Adhesives?

Unlike your everyday glue, structural adhesives are a class of high-performance bonding agents formulated for superior load-bearing capabilities. These specialized adhesives boast a unique epoxy chemical structure that translates to exceptional strength, making them ideal for structural bonding in demanding applications.

The Power of Epoxy in Structural Bonding

The epoxy structure within structural adhesives plays a vital role in their remarkable performance. Epoxies are a class of thermosetting polymers that undergo a permanent chemical reaction during curing. This reaction creates a rigid, high-strength bond that can withstand significant stress – a key advantage in applications like aerospace bonding.

Kohesi Bond: Your Partner in High-Performance Bonding

Kohesi Bond offers a diverse range of structural epoxies specifically designed for the aerospace industry. These aerospace adhesives possess exceptional properties, including:

High tensile strength: Our epoxies can withstand tremendous pulling forces, ensuring the structural integrity of bonded components in aerospace applications.

Excellent durability: Kohesi Bond's epoxies resist extreme temperatures, vibrations, and harsh chemicals, making them ideal for the demanding aerospace environment.

Superior chemical resistance: Our formulations offer exceptional resistance to fuels, solvents, and other chemicals commonly encountered in aerospace applications.

Lightweight properties: Kohesi Bond's space grade epoxies are formulated to be lightweight, minimizing overall weight in aerospace structures.

Beyond Aerospace: Applications of Structural Adhesives

While adhesives in the aerospace industry are a prime example, structural adhesives have diverse applications beyond airplanes and spacecraft. They are crucial in:

Construction: For high-strength bonding of building materials like concrete, steel, and wood.

Automotive Industry: Structural adhesives play a vital role in car manufacturing, bonding body panels and structural components.

Marine Applications: These adhesives excel in boat building due to their excellent water resistance and durability.

By understanding the unique properties of structural adhesives, particularly the strength derived from the epoxy structure, engineers can achieve exceptional results in various demanding applications. For superior structural bonding solutions, Kohesi Bond is your trusted partner. Contact us today to discuss your specific needs.

#structural epoxy#structural adhesive#epoxy chemical structure#epoxy structure#epoxy structural adhesive#structural glue#structural bonding#aerospace adhesive#aerospace bonding#space grade epoxy#adhesives in aerospace industry

1 note

·

View note

Text

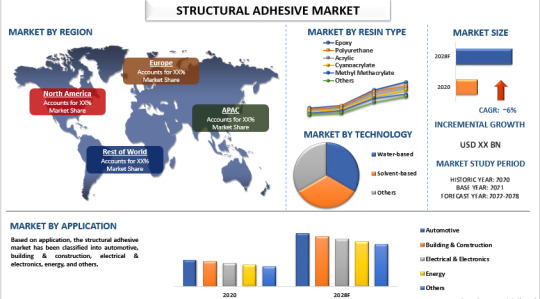

Structural Adhesive Market is expected to grow at a significant rate of around 6% during the forecast period.

0 notes

Text

Mastering the Art of Bonding with Composite Adhesive Techniques

Understanding the composition of composite adhesive is essential for mastering bonding techniques. Typically composed of resins, fillers, and additives, composite adhesive is engineered to create a strong and durable bond between different materials. The precise formulation of these components determines the adhesive's properties, such as curing time, strength, and resistance to environmental factors.

Surface preparation plays a crucial role in ensuring the effectiveness of Composite Adhesive bonding. Before applying the adhesive, surfaces must be clean, dry, and free of any contaminants that could compromise the bond. Proper surface preparation ensures maximum adhesion strength and promotes long-term durability.

Selecting the right application method is vital for achieving optimal bonding results with composite adhesive. Depending on the materials being bonded and the specific requirements of the application, various techniques can be employed, including brush application, spray application, and automated dispensing systems. Each method offers unique advantages and considerations, allowing for precise control over adhesive application and distribution.

Proper curing is essential for maximizing the strength and durability of composite adhesive bonds. Curing refers to the process by which the adhesive undergoes chemical reactions to harden and create a strong bond between the bonded surfaces. Factors such as temperature, humidity, and curing time must be carefully controlled to ensure consistent and reliable bonding results.

Get More Insights On This Topic: Composite Adhesive

#Composite Adhesive#Bonding Agents#Structural Adhesives#Composite Materials#Adhesive Bonding#Industrial Adhesives#Aerospace Adhesives#High Performance Adhesives#Composite Repair Materials

0 notes

Text

Aluminum structural adhesive is a specialized bonding material designed for joining and securing aluminum components in a wide range of applications. This high-performance adhesive is specifically formulated to bond aluminum surfaces with exceptional strength and durability, offering numerous advantages in various industries such as aerospace, automotive, construction, and manufacturing.

0 notes

Text

Unlocking the Potential: Exploring the Structural Adhesive Tapes Market

In the realm of modern construction and manufacturing, structural adhesive tapes have emerged as indispensable components, revolutionizing the way materials are joined and assembled. The structural adhesive tapes market is witnessing substantial growth, driven by their superior bonding strength, versatility, and cost-effectiveness compared to traditional joining methods like welding or mechanical fastening.

One of the primary drivers of the structural adhesive tapes market is their widespread application across various industries, including automotive, aerospace, electronics, construction, and healthcare. These tapes are adept at bonding diverse materials such as metals, plastics, composites, and glass, making them invaluable in a multitude of manufacturing processes.

In the automotive sector, structural adhesive tapes are increasingly used for lightweight vehicle assembly, providing improved fuel efficiency without compromising safety or structural integrity. Similarly, in the aerospace industry, these tapes offer significant weight savings while maintaining stringent performance requirements. Moreover, in the electronics industry, they facilitate miniaturization and enhance product durability.

The construction industry also relies heavily on structural adhesive tapes for bonding facade panels, cladding, insulation materials, and structural elements. Their ability to withstand extreme weather conditions, vibrations, and thermal expansion makes them an ideal choice for modern architectural designs.

Market trends indicate a growing demand for structural adhesive tapes with enhanced properties such as high temperature resistance, UV stability, and excellent adhesion to low-surface-energy substrates. Manufacturers are investing in research and development to meet these evolving needs and gain a competitive edge in the market.

Furthermore, sustainability concerns are driving the adoption of eco-friendly adhesive formulations derived from renewable resources, reducing environmental impact without compromising performance.

As the demand for lightweight, durable, and efficient bonding solutions continues to rise, the structural adhesive tapes market is poised for further expansion. However, challenges such as regulatory compliance, quality control, and pricing pressures remain significant considerations for industry players.

In conclusion, the structural adhesive tapes market represents a dynamic landscape with immense potential for growth and innovation. With advancements in materials science and manufacturing technologies, these tapes are reshaping the way we build, assemble, and create, driving progress across various sectors and contributing to a more sustainable future.

#Structural Adhesive Tapes#Adhesive Market#Industrial Adhesives#Construction Materials#Market Trends#technology

0 notes

Text

Structural Adhesives Market Share, Size and Trends | 2031

The Insight Partners has raised the bar with its latest findings titled "Global Structural Adhesives Market Share, Size and Trends | 2031", presenting a comprehensive Structural Adhesives market analysis that promises to reshape industry dynamics. Leveraging advanced methodologies and innovative approaches, our firm has uncovered trends and insights that are poised to guide businesses toward unparalleled success.

In a market characterized by rapid changes, The Insight Partners has diligently conducted extensive research to provide clients with a strategic advantage. The recently concluded study delves into critical aspects of the industry, unraveling Structural Adhesives market trends and patterns that demand immediate attention.

Structural Adhesives Market forecasts are combined with the economies of scale delineated by market size, growth rate, and compound annual growth rate. To examine demand drivers and constraints before other market actors, this chapter is even more crucial. Companies may better manage their goods and place themselves in the market gap by understanding market trends. Analysis of the business environment based on several models is provided in this section. Businesses must streamline their success and income streams to be competitive in the industry. Businesses may map the economic, environmental, and legal issues and update their unique selling propositions.

Some key findings include:

Emerging Market Opportunities: We identify lucrative opportunities that are set to emerge in the forecast period, allowing businesses to capitalize on market shifts and gain a competitive edge.

Consumer Behavior Insights: In an era of evolving consumer preferences, understanding the nuances of consumer behavior is crucial. Our research sheds light on changing buying patterns, enabling businesses to tailor their strategies to meet customer expectations effectively.

Technological Disruptions: Technology continues to be a driving force in shaping industries. Structural Adhesives market report’s in-depth analysis pinpoints technological disruptions, offering businesses foresight into potential game-changers and threats on the horizon.

Competitive Business Matrix: The competitor's analysis offered in this report emphasizes covering key companies in the Structural Adhesives market. A brief discussion of leading market players and their business strategies intends to offer essential details needed for a competitive edge.

Some companies in Structural Adhesives market are:

3M

Ashland

Bostik

H.B.Fuller

HenkelAG&Co.KGaA

HuntsmanInternationalLLC.

IllinoisToolWorksInc.

LordCorporation

SikaAG

TheDOWChemicalCompany

Research Methodology:

Most research studies use a combination of both primary and secondary research methods to ensure comprehensive and accurate data analysis. The specific methodology used in the Structural Adhesives market research study will depend on various factors such as the research objectives, the target audience, and the available resources.

Go-To-Market Framework:

Development trends, competitive landscape analysis, supply-side analysis, demand-side analysis, year-on-year growth, competitive benchmarking, vendor identification, CMI quadrant, and other significant analysis, as well as development status.

Customized regional/country reports as per request and country-level analysis.

Potential & niche segments and regions exhibiting promising Structural Adhesives market growth are covered.

Analysis of Structural Adhesives Market Size (historical and forecast), Total Addressable Market (TAM), Serviceable Available Market (SAM), Serviceable Obtainable Market (SOM), Market Growth, Technological Trends, Market Share, Market Dynamics, Competitive Landscape, and Major Players (Innovators, Start-ups, Laggard, and Pioneer).

On the Basis of Resin this market is categorized further into-

Epoxy

Polyurethane

Acrylic

Methyl Methacrylate

Cyanoacrylate

Others

On the Basis of Substrate this market is categorized further into-

Metals

Plastics

Wood

Composites

Others

On the Basis of Applications this market is categorized further into-

Building and Construction

Automotive

Aerospace

Wind Energy

Marine

Rail

Other Applications

Key regions Structural Adhesives Market Research Report:

North America (U.S., Canada, Mexico)

Europe (U.K., France, Germany, Spain, Italy, Central & Eastern Europe, CIS)

Asia Pacific (China, Japan, South Korea, ASEAN, India, Rest of Asia Pacific)

Latin America (Brazil, Rest of Latin America)

The Middle East and Africa (Turkey, GCC, Rest of the Middle East and Africa)

Rest of the World

About Us:

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

Contact Us: : www.theinsightpartners.com

0 notes